Factory For Stainless Steel 304 Conveyor Belting - Semi-Automatic Pouring Machine – Kailong Machinery Detail:

Semi-automatic pouring machine is suited for work in semi-automatic mode,guided by operator with joystick. consist of fan-shaped pouring ladle, servo tilting mechanism, longitudinal vehicle rail system, transferring system,control and operation system,safe system, cable device, stream inoculation device, etc. With three freedom of longitudinal travels,transverse travels and tilt pouring , it’s widely used in all kinds of moulding line for grey iron, ductile iron,included flask moulding and none-flask moulding line.

Ladle transport: By crane or forklift.

Ladle capacity: 1000kg-2500kg.

Pouring speed: 15-22kg/sec.

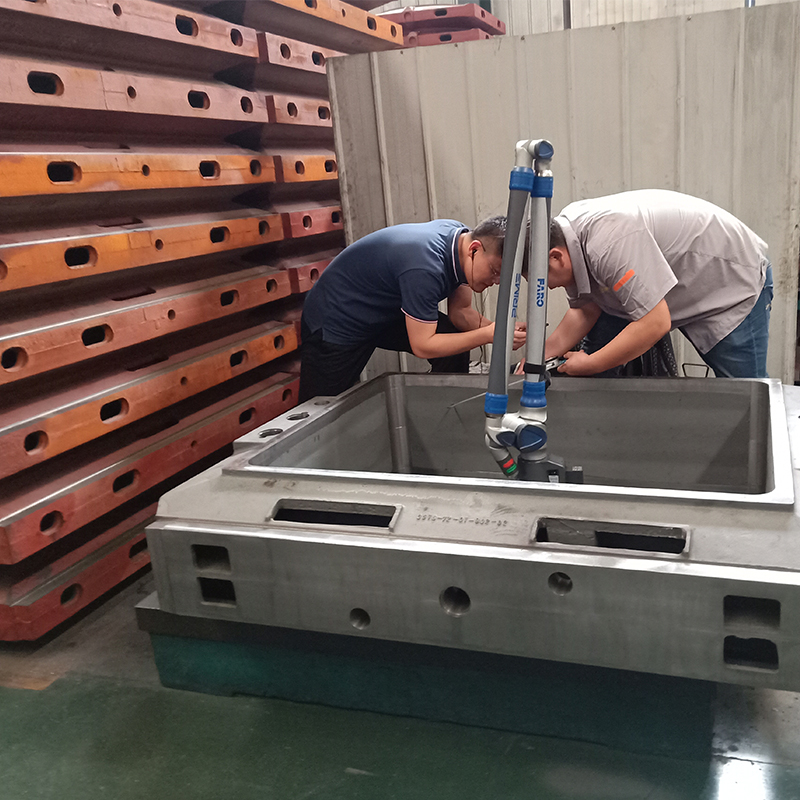

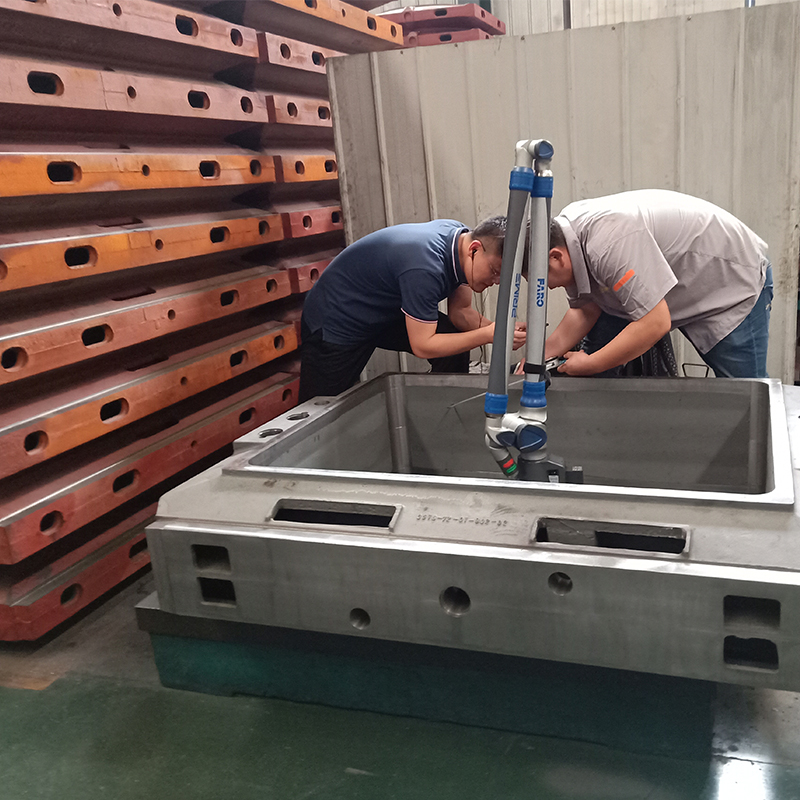

Product detail pictures:

Related Product Guide:

Modern Era Molding Machines and Industrial Machines

What is Injection Moulding?

The really abundant projects administration experiences and just one to one particular provider model make the substantial importance of organization communication and our easy understanding of your expectations for Factory For Stainless Steel 304 Conveyor Belting - Semi-Automatic Pouring Machine – Kailong Machinery, The product will supply to all over the world, such as: Kuwait , United Kingdom , Adelaide , To make every client satisfied with us and achieve win-win success, we will continue to try our best to serve and satisfy you! Sincerely looking forward to cooperating with more overseas customers based on mutual benefits and great future business. Thank you.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.

-

China Gold Supplier for 19l Water Bottle Blowin...

View Detail -

100% Original Bottle Blow Molding Machine - Ap...

View Detail -

OEM manufacturer Liquer Pouring Machine - Stat...

View Detail -

Factory directly supply Quarry Sand Crushing Eq...

View Detail -

Free sample for Small Candy Making Machine - A...

View Detail -

Top Suppliers Pvc Sheet Production Line - Flas...

View Detail