factory low price Brake Pads Back Plates Spraying Line - Continuous Mechanized Moulding Line – Kailong Machinery Detail:

XZ14 Series Joet-Squeeze Moulding Line is the ideal equipment in mass production for foundry factory. Its advantages are less investment, quick returns, reduce labor intensity, raise cast quality, easy operation and maintenance.

The kind of moulding line adopt the joet-squeeze moulding machine, the mould conveyer transfer casting mould go on pouring with cool. The worker carry flask and sand mould through air hang, as well as core filling, match flask, and pouring etc, process adopt semi-automatic operation, the roller machine return flask.

Major equipments compositions are as follows:

◆XZ14 Series Joet-Squeeze Moulding Machine (according to flask size).

◆Mould conveyer.

◆Two way air hang.

◆Poring ring rail, Ladle etc.

◆Fall sand machine.

◆Return flask transport roller machine.

◆Flask (single wall,material:ductile iron).

◆ Y21 Series Mould Conveyer

This machine, the equipment collocated for moulding line, makes different process such as moulding, core filling, casting, flask shaking be connected together to form a close moulding line. It is the ideal equipment to realize the moulding mechanization and automation. Generally, it is continuously sperated, but can be beam walking style also as the requirement. The whole length and layout depends on the moulding specifications and the conditions of the workshop.

The Specification Of Continuous Mechanized Moulding Line

| Model | Size Of Pallet Car |

Pitch Of Pallet Car |

Hight Of Pallet Car |

Min Radius Of Turn |

Number Of Rollers |

Motion Speed |

| Y2108 | 800*500 | 1000 | 500 | 1500 | 2 |

1.7-5.8m/min

Adjustable Speed

|

| Y2108A | 4 | |||||

| Y2110 | 1000*650 | 1334 | 500 | 2000 | 4 | |

| Y2110A | ||||||

| Y2112 | 1280*680 | 1668 | 600 | 2500 | 4 | |

| Y2114 | 1400*900 | 1668 | 600 | |||

| Y2116 | 1600*1000 | 2000 | 600 |

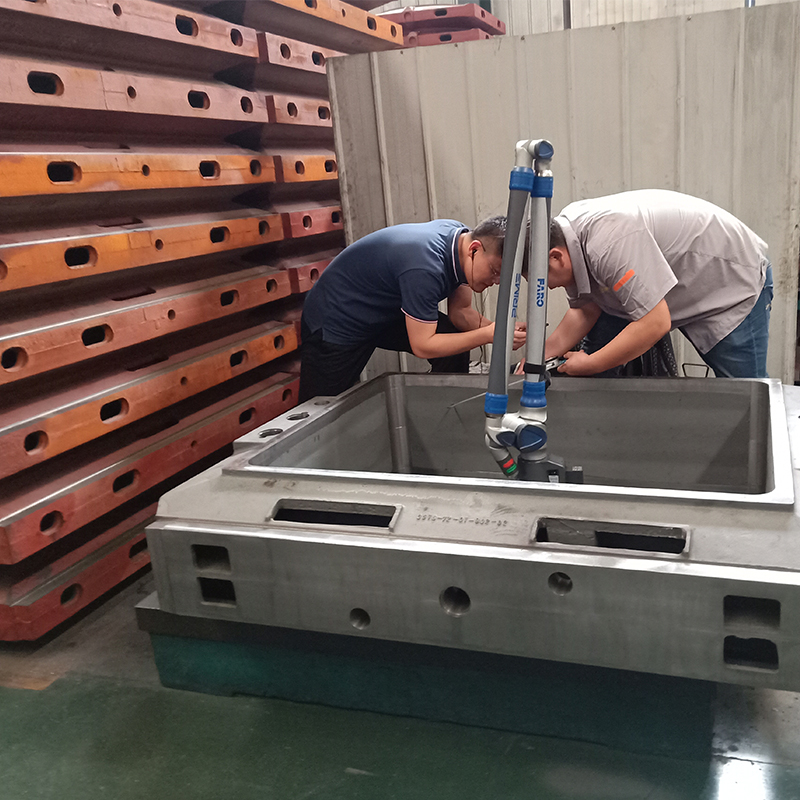

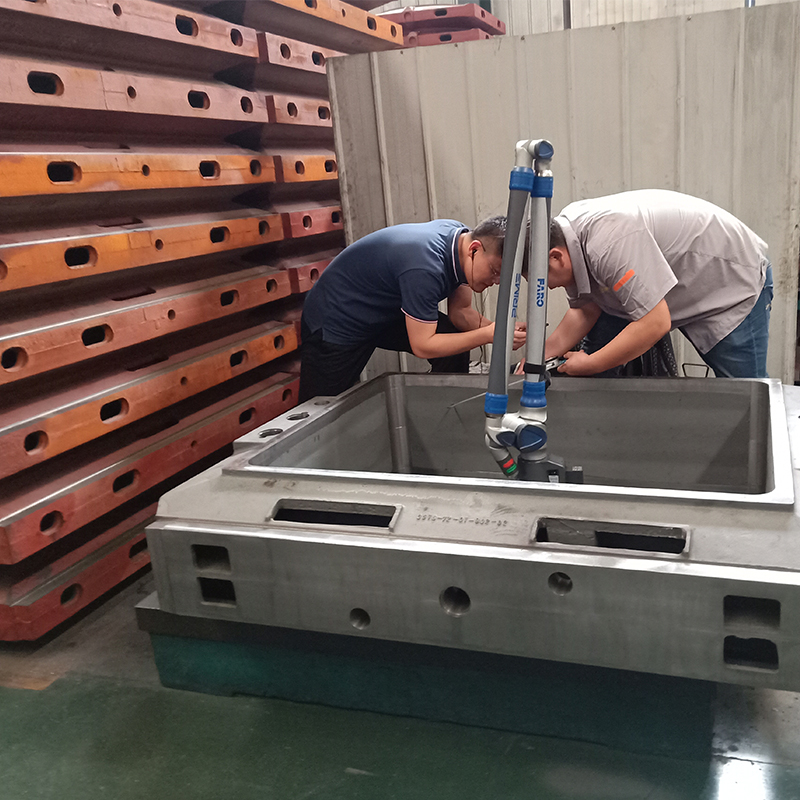

Product detail pictures:

Related Product Guide:

What is Injection Moulding?

Modern Era Molding Machines and Industrial Machines

We've been proud with the significant shopper fulfillment and wide acceptance due to our persistent pursuit of top of the range both of those on solution and repair for factory low price Brake Pads Back Plates Spraying Line - Continuous Mechanized Moulding Line – Kailong Machinery, The product will supply to all over the world, such as: Austria , Saudi Arabia , Lithuania , They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a really should in your case of excellent good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we've been planning to possess a vibrant prospect and to be distributed all over the world within the years to come.

This company has the idea of better quality, lower processing costs, prices are more reasonable, so they have competitive product quality and price, that's the main reason we chose to cooperate.

-

OEM manufacturer Xps Cornice Production Line - ...

View Detail -

OEM manufacturer Used Pet Bottle Blowing Machin...

View Detail -

OEM Manufacturer Tofu Machine Maker - Moulding...

View Detail -

Factory Free Sample Transfer Car - Flask Of Di...

View Detail -

Low price for Check Weigher Indicator - Flask ...

View Detail -

factory customized Concrete Pump Price - Flask...

View Detail