High Quality for Small Blow Moulding Machine - Automatic, Semi-Automatic Flask Moulding Line – Kailong Machinery Detail:

According to the different requirements of customers, Kailong Machinery supply tailor – made solutions to customers of moulding machine and moulding line, including:

◆Hydraulic multi-piston squeeze moulding machine and automatic, semi-automatic moulding line.

◆Hydraulic plate squeeze moulding machine and automatic, semi-automatic moulding line.

◆Pneumatic multi-piston squeeze moulding machine and automatic, semi-automatic moulding line.

This moulding line adopts PLC to control running beats, hydraulic and motor reducer drive, including moulding machine and auxiliary machine (flask punch-out device, flask separating device, top surface of pallet car cleaning device, flask outside shape cleaning and checking device, turnover device, sand cutting device, downgate drilling device, vote hole drilling device, core setting device, flask closing device, transfer car between moulding section and cooling section, indexing transport and cushioning device, rail system), electric control system, hydraulic system, safe device and etc. Core setting, flask closing and pouring can be applied at statically.

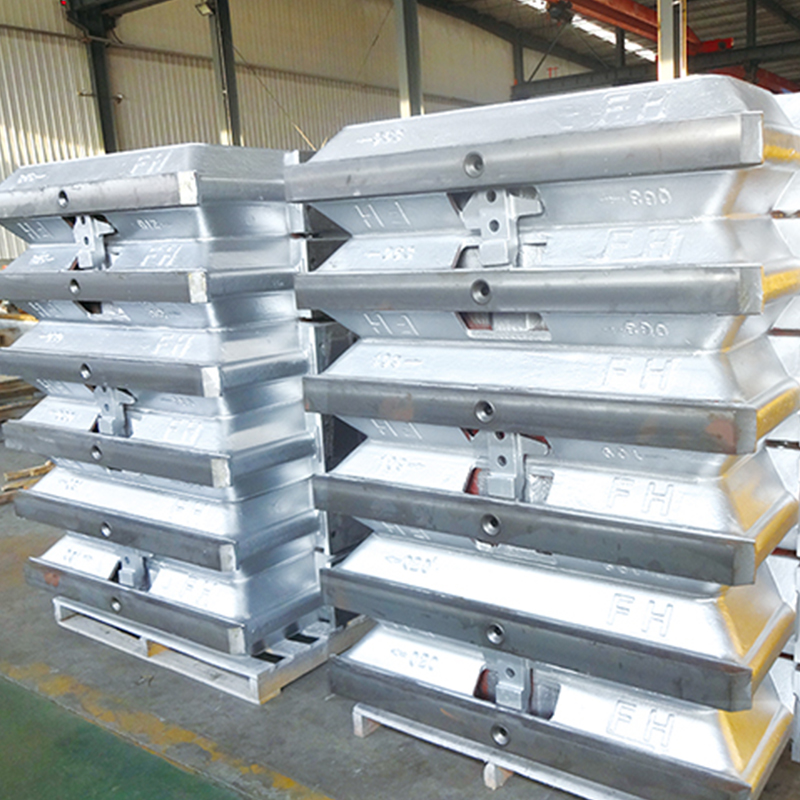

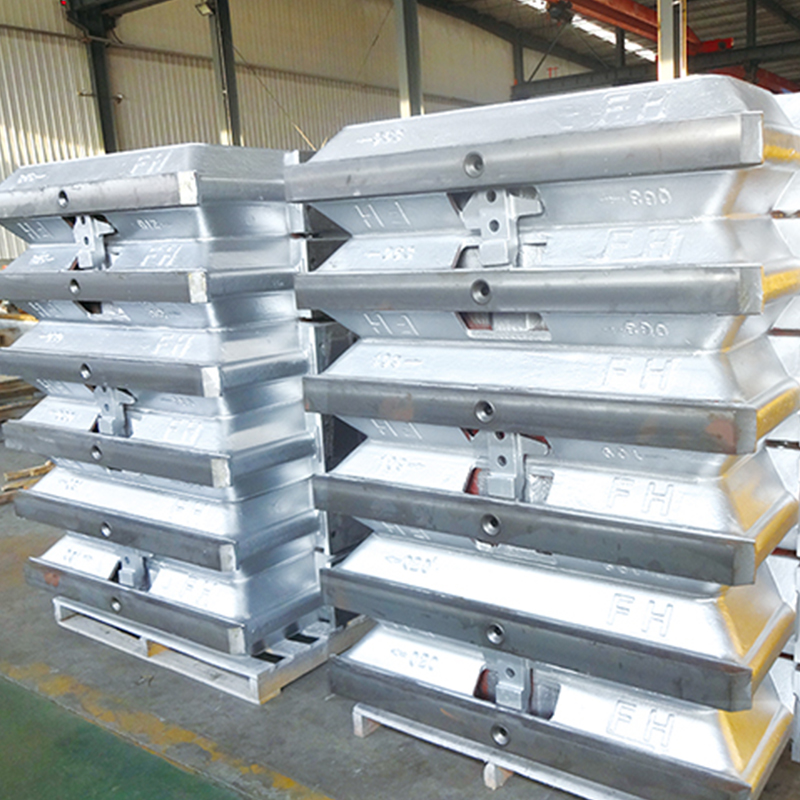

Product detail pictures:

Related Product Guide:

What is Injection Moulding?

Modern Era Molding Machines and Industrial Machines

We have probably the most state-of-the-art output equipment, experienced and qualified engineers and workers, recognized good quality manage systems plus a friendly skilled income workforce pre/after-sales support for High Quality for Small Blow Moulding Machine - Automatic, Semi-Automatic Flask Moulding Line – Kailong Machinery, The product will supply to all over the world, such as: Greek , Barbados , Jamaica , Good quality, Good service is always our tenet and credo. We take every effort to control the quality, package, labels etc and our QC will check every detail during producing and before shipment. We are willing to establish long business relationship with those who seek the high quality products and good service. We have set up a wide sales network across European countries, North of America, South of America, Middle East, Africa, East Asia countries.Please contact us now, you will find our professional experience and high quality grades will contribute to your business.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.

-

OEM Customized Automatic Pu Shoe Injection Mach...

View Detail -

Factory selling Apron Feeder Conveyor Chain - ...

View Detail -

Factory Price Jar Embryo Moulding Equipment - ...

View Detail -

Chinese wholesale Film Extrusion Machines - Hi...

View Detail -

Discount Price Qingdao Hegu Wpc Machine - Auto...

View Detail -

Factory Free sample Pu Sole Making Machine - F...

View Detail