Low price for Injection Molding Machine Spare Parts - Air multi-piston moulding machine – Kailong Machinery Detail:

1. Moderate pressure, no special requirements for sand, and the number of contacts more than 60, suitable for complex model modeling.

2. During compaction, the frame is free of force. The contacts extend downward, the pressure strength is the internal force of compaction.

3. The effect of shock compaction is good. The hardness of the sand mould is high and even.

4. This machine adopts the spring full buffer pneumatic micro vibration mechanism, so it has no special requirement for the foundation, and the mould lifting adopts the connecting rod.

5. Synchronous shaft structure, speed regulation of pneumatic oil, good mould synchronization with free speed control.

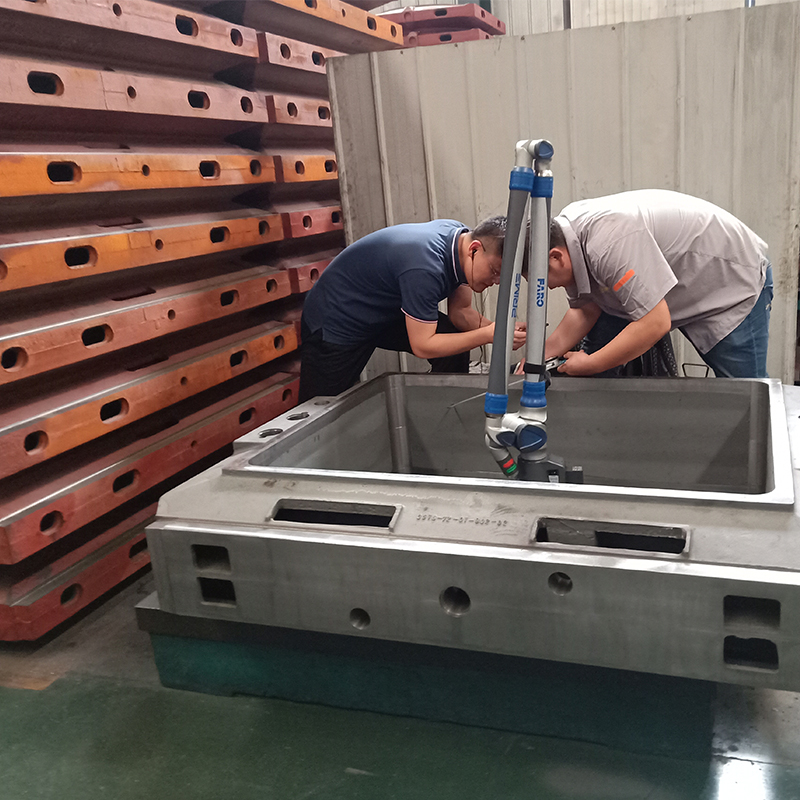

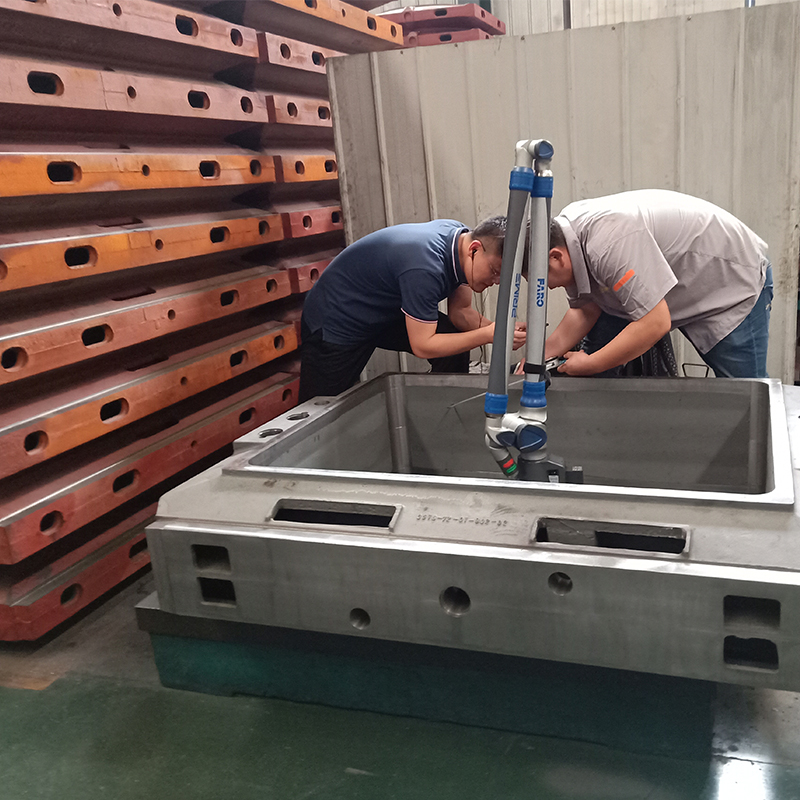

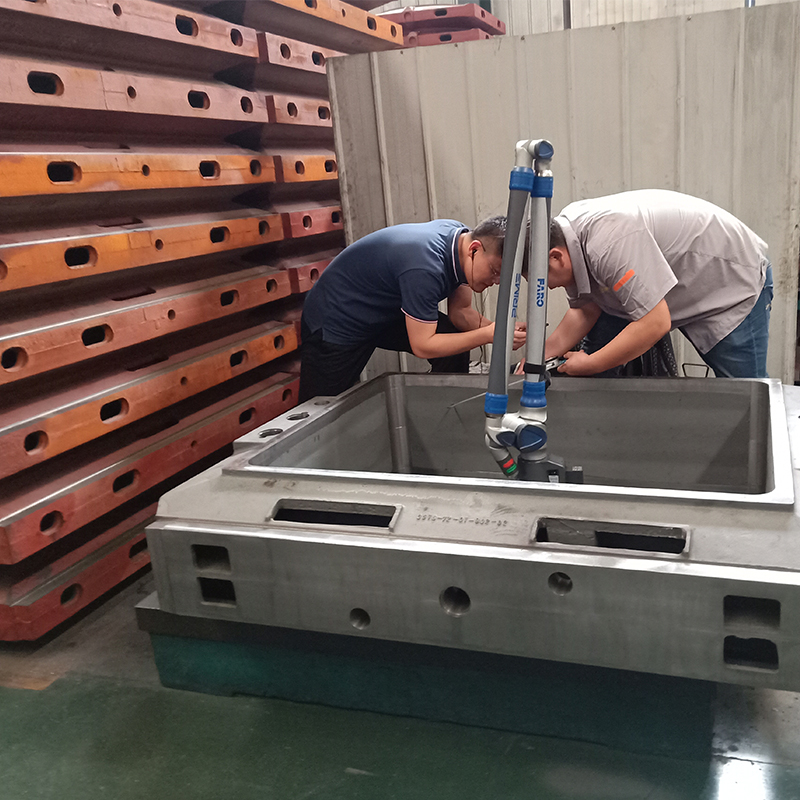

Product detail pictures:

Related Product Guide:

What Do You Need To Know About Your Injection Moulding Machine?

Injection Moulding Design and Tooling

We now have a skilled, performance team to supply good quality services for our consumer. We often follow the tenet of customer-oriented, details-focused for Low price for Injection Molding Machine Spare Parts - Air multi-piston moulding machine – Kailong Machinery, The product will supply to all over the world, such as: Irish , India , Ukraine , As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products we offer, effective and satisfying consultation service is supplied by our specialist after-sale service group. Solution lists and detailed parameters and any other info weil be sent to you timely for the inquiries. So please get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we are going to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!

-

Best-Selling Automatic Cut To Lenth Lines - Fl...

View Detail -

PriceList for High Pressure Multi-Piston Mouldi...

View Detail -

18 Years Factory Injection Blow Moulding Machin...

View Detail -

OEM Supply Hot Sell Machine - Open Mechanized ...

View Detail -

PriceList for Automatic High Pressure Flasked M...

View Detail -

OEM Factory For Sand Mixer - Flask Of Dimensio...

View Detail