Massive Selection for Inexpensive Servo Blow Molding Machine - Static Pressure Automatic Moulding Line of Green Sand – Kailong Machinery Detail:

Static pressure moulding technical refers to airflow with hydraulic multi-piston squeeze compaction technology, according to the difficulty of compaction, can choose only hydraulic multi-piston squeeze compaction or airflow and hydraulic multi-piston squeeze compaction.

Static Pressure has following advantages.

◆High ability for compaction sand, rigid and dense mould, suitable to manufacture of complex castings.

◆Dimensional stability and better surface roughness.

◆High efficiency of moulding.

◆Mould plate with high rate of utilization.

◆Good working condition and labour saving.

Kailong Machinery is committed to providing customers with the most valuable Static Pressure Automatic Moulding Line, to ensure the moulding line work effectively and reliably by high performance of configuration.

–The mechanical parts of main and auxiliary equipments machining by CNC machine, the necessary heat treatment to guarantee precision and service life.

–PLC from SimensS7, with touch screen and network Ethernet etc.

–Servo system from SEW or Siemens and and Variable-Frequency Drive from Rexroth.

–Hydraulic valve of moulding machine from Rexroth, Hydraulic Cylinder from China famous brand.

–Low-voltage electrical components from Schneide.

–Hydraulic Seals from international brand.

–Bearing from China famous brand (HRB/LYC/ZWZ).

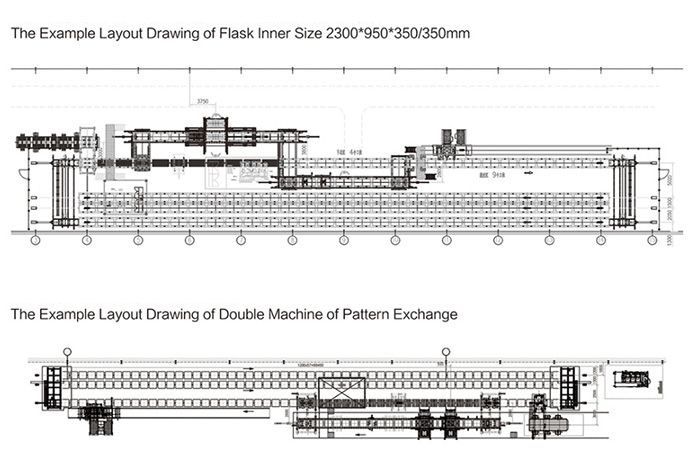

The Example Layout Drawing of Single-Station Machine of Pattern Turnover:

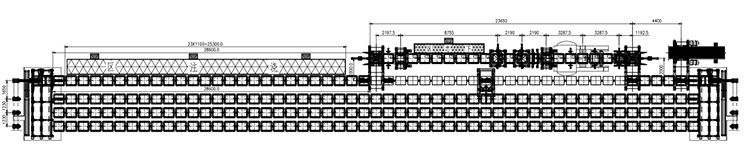

Typical Specification of Single-Station Moulding Line

| Item | Model | |||

| KSP80 | KSP100 | KSP120 | KSP230 | |

| Flask Inner Size(mm) | 800x600x200/200 | 1000x1000x250/250 | 1200x800x350/350 | 2300x950x350/350 |

| Moulding Speed(sec/cycle) | 30 | 30 | 36 | 60 |

| Specific Squeeze Pressure(kgf/cm2) | 8~12 | 8~12 | 8~12 | 8~12 |

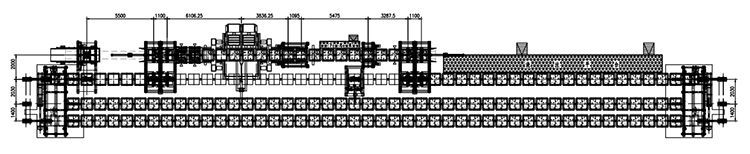

The Example Layout Drawing of Double-Station Machine of Pattern Exchange

Typical Specification of Double-Station Moulding Line

| Item | Model | ||

| SPD80 | SPD100 | SPD120 | |

| Flask Inner Size(mm) | 800x600x200/200 | 1000x1000x250/250 | 1200x800x350/350 |

| Moulding Speed(sec/cycle) | 20 | 20 | 24 |

| Specific Squeeze Pressure(kgf/cm2) | 8~12 | 8~12 | 8~12 |

Product detail pictures:

Related Product Guide:

Modern Era Molding Machines and Industrial Machines

How Does an Injection Moulding Machine Work?

Assume full responsibility to satisfy all needs of our clients; achieve continual advancements by endorsing the expansion of our purchasers; turn into the final permanent cooperative partner of clientele and maximize the interests of clients for Massive Selection for Inexpensive Servo Blow Molding Machine - Static Pressure Automatic Moulding Line of Green Sand – Kailong Machinery, The product will supply to all over the world, such as: Marseille , Argentina , Eindhoven , we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, we have gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

The company keeps to the operation concept scientific management, high quality and efficiency primacy, customer supreme, we have always maintained business cooperation. Work with you,we feel easy!

-

Competitive Price for Sand Making Stones Price ...

View Detail -

China OEM Foundry Produce Line - Flask for Mou...

View Detail -

Fast delivery Recycling Machine Price - Apron ...

View Detail -

China New Product Slat Chain Bottle Conveyor - ...

View Detail -

Manufacturing Companies for Chocolate Coating M...

View Detail -

High Quality Machine Injection Plastic - Flask...

View Detail