New Delivery for Jar Blow Molding Machine - Automatic Horizontal Flaskless Moulding Line – Kailong Machinery Detail:

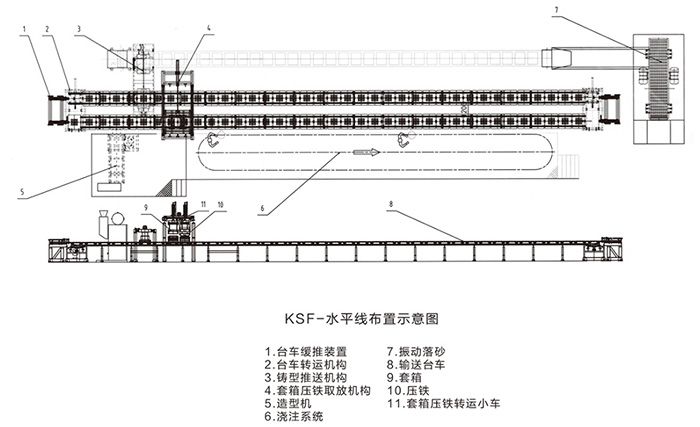

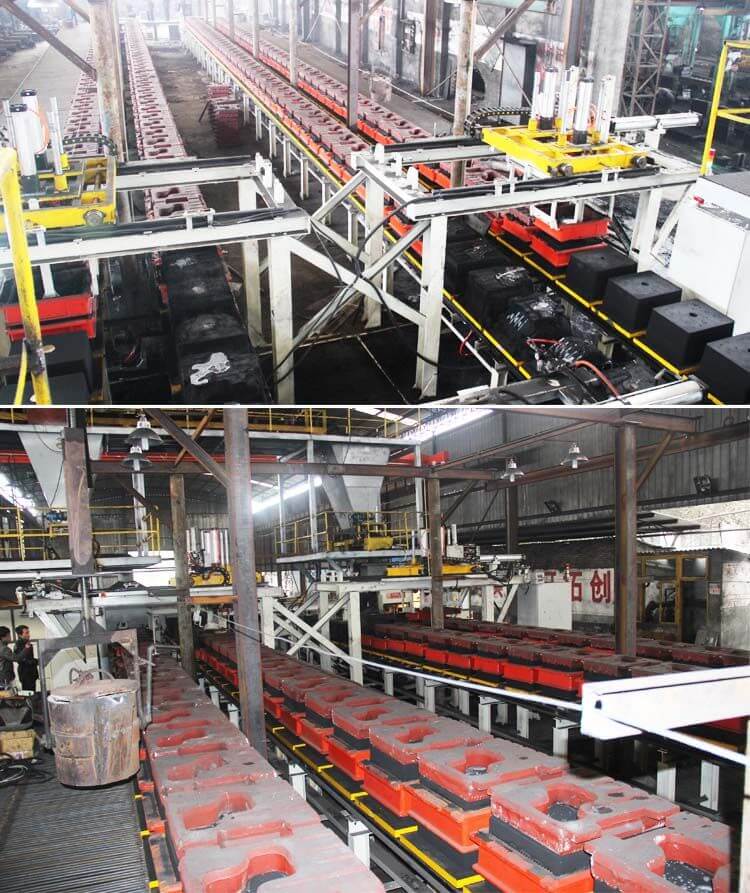

KSF horizontal parting and flask-striped shooting-squeezing molding line adopt the sand shooting, with horizontal parting, slip flask and weight. Easy core setting, easy operation, high automation, the molding lines are widely used in mass-production for small-sized castings. The whole line consist of molding machine, sand conveyor line, slip flask and weight taking and droping device, indexing transport and cushioning device, synchronous cooling belt, pouring machine, etc.

Typical Specification of Moulding Machine

| Item | Model | ||

| KSF50 | KSF60 | KSF70 | |

| Flask Inner Size(mm) | 500x400x150/150 | 600x500x200/200 | 700x600x250/250 |

| Moulding Speed(Without Core Setting) | 30 | 30 | 36 |

| Specific Squeeze Pressure(kgf/cm2) | 8~12 | 8~12 | 8~12 |

Product detail pictures:

Related Product Guide:

Injection Moulding Design and Tooling

How Does an Injection Moulding Machine Work?

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of New Delivery for Jar Blow Molding Machine - Automatic Horizontal Flaskless Moulding Line – Kailong Machinery, The product will supply to all over the world, such as: Pakistan , Dubai , United Arab Emirates , We are looking forward to establishing a mutually beneficial relationship with you based on our high-quality products, reasonable prices and best service. We hope that our products will bring you a pleasant experience and carry a feeling of beauty.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.

-

Quality Inspection for Floral Foam Machinery - ...

View Detail -

PriceList for Plastic Blow Moulding Machine - ...

View Detail -

OEM manufacturer Used Pet Bottle Blowing Machin...

View Detail -

18 Years Factory Injection Blow Moulding Machin...

View Detail -

High definition Portable Beer Dispenser - Flas...

View Detail -

Manufacturer for Blow Molding Machine - High Q...

View Detail