OEM/ODM Manufacturer Plastic Suction Hose Extrusion Line - Static Pressure Automatic Moulding Line of Green Sand – Kailong Machinery Detail:

Static pressure moulding technical refers to airflow with hydraulic multi-piston squeeze compaction technology, according to the difficulty of compaction, can choose only hydraulic multi-piston squeeze compaction or airflow and hydraulic multi-piston squeeze compaction.

Static Pressure has following advantages.

◆High ability for compaction sand, rigid and dense mould, suitable to manufacture of complex castings.

◆Dimensional stability and better surface roughness.

◆High efficiency of moulding.

◆Mould plate with high rate of utilization.

◆Good working condition and labour saving.

Kailong Machinery is committed to providing customers with the most valuable Static Pressure Automatic Moulding Line, to ensure the moulding line work effectively and reliably by high performance of configuration.

–The mechanical parts of main and auxiliary equipments machining by CNC machine, the necessary heat treatment to guarantee precision and service life.

–PLC from SimensS7, with touch screen and network Ethernet etc.

–Servo system from SEW or Siemens and and Variable-Frequency Drive from Rexroth.

–Hydraulic valve of moulding machine from Rexroth, Hydraulic Cylinder from China famous brand.

–Low-voltage electrical components from Schneide.

–Hydraulic Seals from international brand.

–Bearing from China famous brand (HRB/LYC/ZWZ).

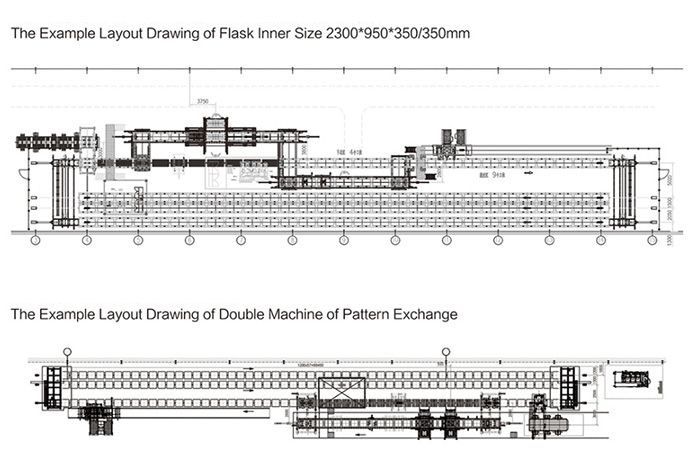

The Example Layout Drawing of Single-Station Machine of Pattern Turnover:

Typical Specification of Single-Station Moulding Line

| Item | Model | |||

| KSP80 | KSP100 | KSP120 | KSP230 | |

| Flask Inner Size(mm) | 800x600x200/200 | 1000x1000x250/250 | 1200x800x350/350 | 2300x950x350/350 |

| Moulding Speed(sec/cycle) | 30 | 30 | 36 | 60 |

| Specific Squeeze Pressure(kgf/cm2) | 8~12 | 8~12 | 8~12 | 8~12 |

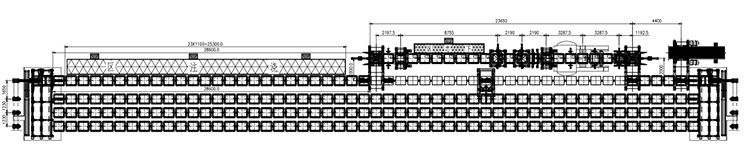

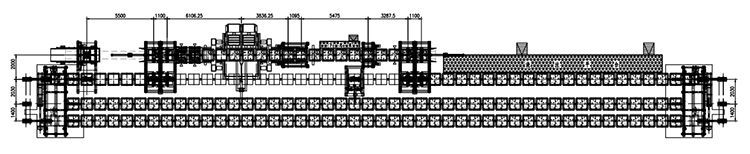

The Example Layout Drawing of Double-Station Machine of Pattern Exchange

Typical Specification of Double-Station Moulding Line

| Item | Model | ||

| SPD80 | SPD100 | SPD120 | |

| Flask Inner Size(mm) | 800x600x200/200 | 1000x1000x250/250 | 1200x800x350/350 |

| Moulding Speed(sec/cycle) | 20 | 20 | 24 |

| Specific Squeeze Pressure(kgf/cm2) | 8~12 | 8~12 | 8~12 |

Product detail pictures:

Related Product Guide:

Modern Era Molding Machines and Industrial Machines

Injection Moulding Design and Tooling

We not only will try our greatest to present fantastic expert services to each purchaser, but also are ready to receive any suggestion offered by our prospects for OEM/ODM Manufacturer Plastic Suction Hose Extrusion Line - Static Pressure Automatic Moulding Line of Green Sand – Kailong Machinery, The product will supply to all over the world, such as: Slovakia , Portugal , France , On today, we've got customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to deliver the highest quality products with best price. We've been looking forward to doing business with you!

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!

-

Factory directly supply Roof Tile Making Machin...

View Detail -

China New Product Cnc Machine Belt Type Chip Co...

View Detail -

Reliable Supplier Apron Conveyor For Big Bulk M...

View Detail -

Top Quality Small Extrusion Blow Moulding Machi...

View Detail -

Factory Cheap Small Pet Machine - Moulding Fla...

View Detail -

Discount Price Shoe Sole Pouring Machine - Apr...

View Detail