Quality Inspection for Candle Production Line - Continuous Mechanized Moulding Line – Kailong Machinery Detail:

XZ14 Series Joet-Squeeze Moulding Line is the ideal equipment in mass production for foundry factory. Its advantages are less investment, quick returns, reduce labor intensity, raise cast quality, easy operation and maintenance.

The kind of moulding line adopt the joet-squeeze moulding machine, the mould conveyer transfer casting mould go on pouring with cool. The worker carry flask and sand mould through air hang, as well as core filling, match flask, and pouring etc, process adopt semi-automatic operation, the roller machine return flask.

Major equipments compositions are as follows:

◆XZ14 Series Joet-Squeeze Moulding Machine (according to flask size).

◆Mould conveyer.

◆Two way air hang.

◆Poring ring rail, Ladle etc.

◆Fall sand machine.

◆Return flask transport roller machine.

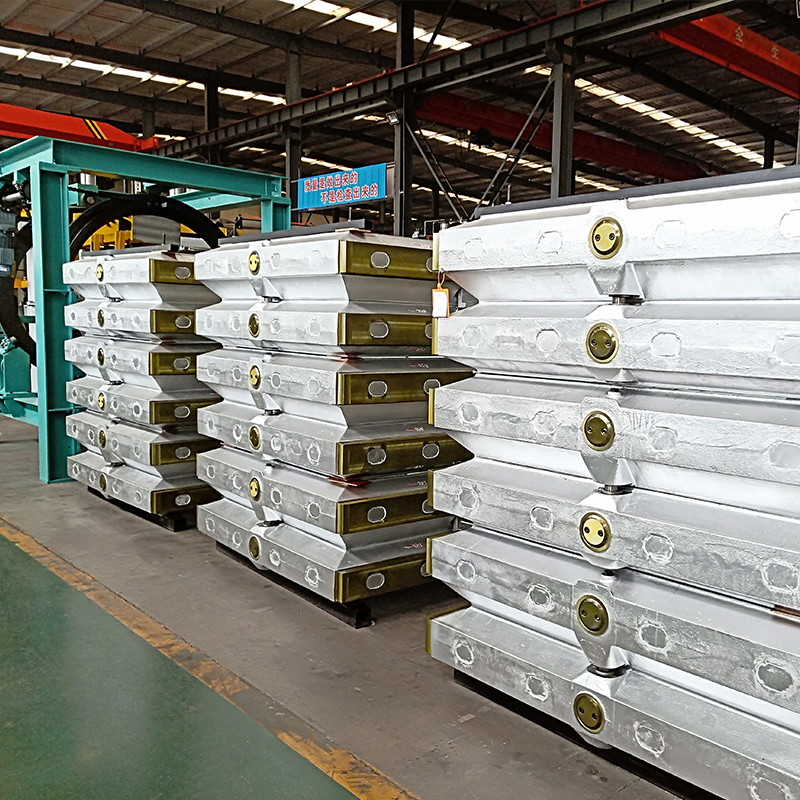

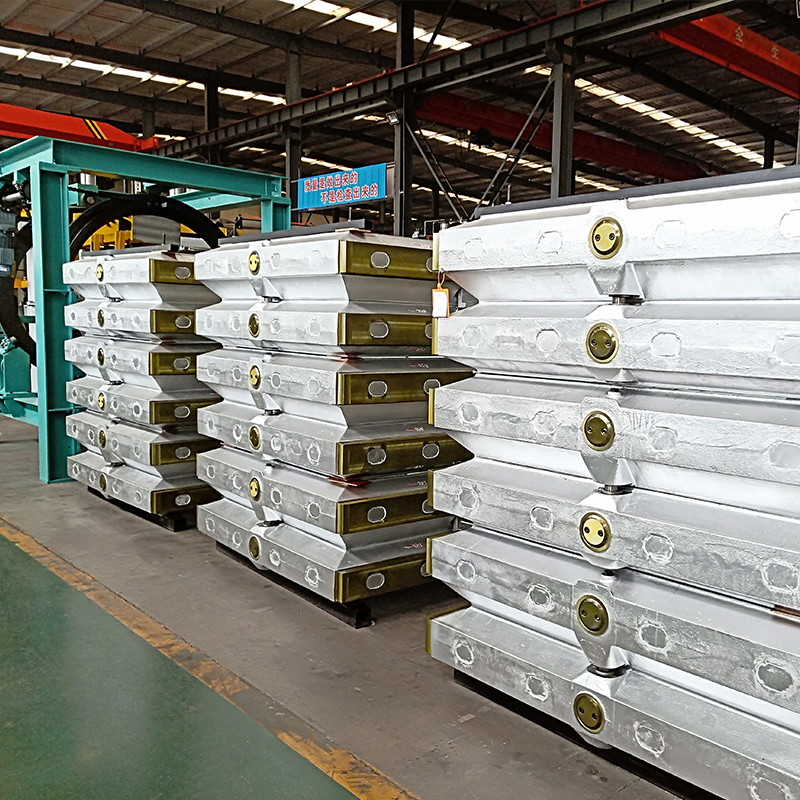

◆Flask (single wall,material:ductile iron).

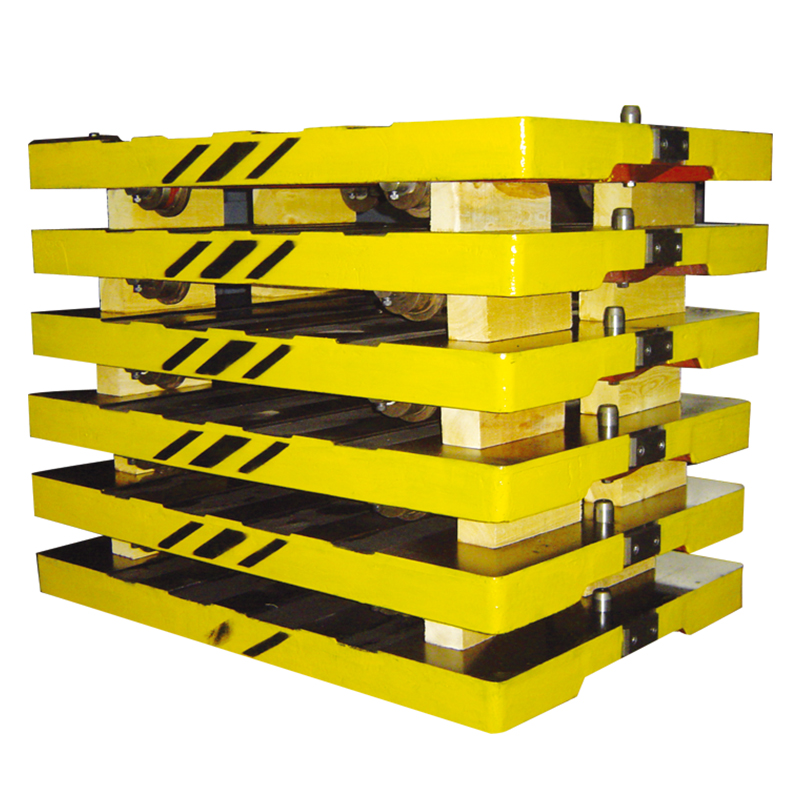

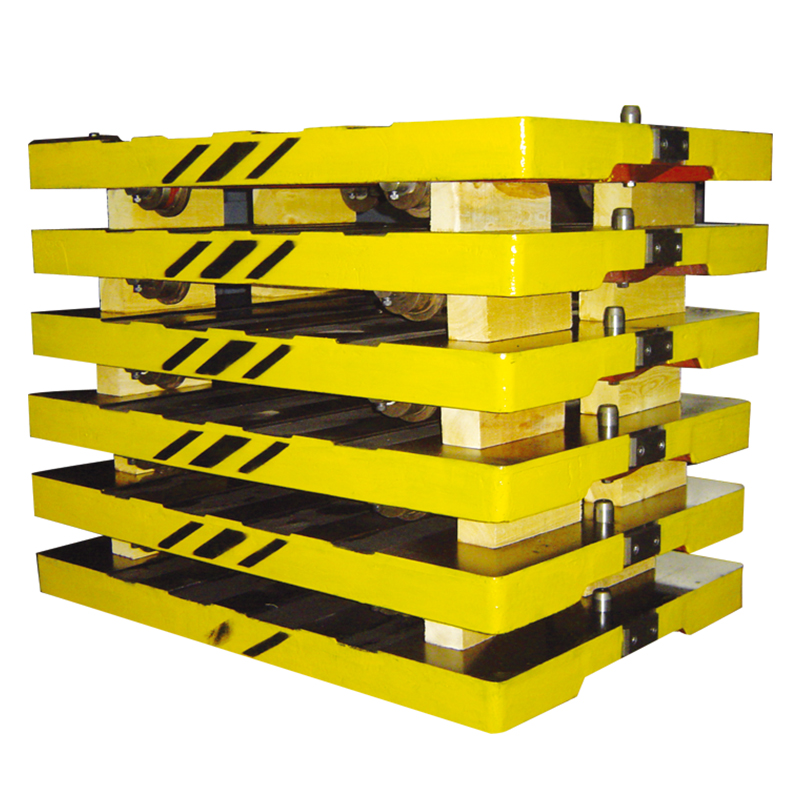

◆ Y21 Series Mould Conveyer

This machine, the equipment collocated for moulding line, makes different process such as moulding, core filling, casting, flask shaking be connected together to form a close moulding line. It is the ideal equipment to realize the moulding mechanization and automation. Generally, it is continuously sperated, but can be beam walking style also as the requirement. The whole length and layout depends on the moulding specifications and the conditions of the workshop.

The Specification Of Continuous Mechanized Moulding Line

| Model | Size Of Pallet Car |

Pitch Of Pallet Car |

Hight Of Pallet Car |

Min Radius Of Turn |

Number Of Rollers |

Motion Speed |

| Y2108 | 800*500 | 1000 | 500 | 1500 | 2 |

1.7-5.8m/min

Adjustable Speed

|

| Y2108A | 4 | |||||

| Y2110 | 1000*650 | 1334 | 500 | 2000 | 4 | |

| Y2110A | ||||||

| Y2112 | 1280*680 | 1668 | 600 | 2500 | 4 | |

| Y2114 | 1400*900 | 1668 | 600 | |||

| Y2116 | 1600*1000 | 2000 | 600 |

Product detail pictures:

Related Product Guide:

How Does an Injection Moulding Machine Work?

Injection Moulding Design and Tooling

Our eternal pursuits are the attitude of regard the market, regard the custom, regard the science plus the theory of quality the basic, have faith in the main and management the advanced for Quality Inspection for Candle Production Line - Continuous Mechanized Moulding Line – Kailong Machinery, The product will supply to all over the world, such as: Holland , Denver , Malta , Company name, is always regarding quality as company' s foundation, seeking for development via high degree of credibility , abiding by ISO quality management standard strictly, creating top-ranking company by spirit of progress-marking honesty and optimism.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!

-

Factory Price Plastic Pipe Production Line - M...

View Detail -

Best Price on Cope Turnover - Flask Manufactur...

View Detail -

factory customized Pp Strapping Extruder - Air...

View Detail -

PriceList for Clay Sand Casting Machine - Flas...

View Detail -

2017 wholesale price Macaroni Pasta Production ...

View Detail -

OEM/ODM Supplier Apron Kitchen Sink - pallet c...

View Detail