Reasonable price Automatic Barley Fodder Machine - Static Pressure Automatic Moulding Line of Green Sand – Kailong Machinery Detail:

Static pressure moulding technical refers to airflow with hydraulic multi-piston squeeze compaction technology, according to the difficulty of compaction, can choose only hydraulic multi-piston squeeze compaction or airflow and hydraulic multi-piston squeeze compaction.

Static Pressure has following advantages.

◆High ability for compaction sand, rigid and dense mould, suitable to manufacture of complex castings.

◆Dimensional stability and better surface roughness.

◆High efficiency of moulding.

◆Mould plate with high rate of utilization.

◆Good working condition and labour saving.

Kailong Machinery is committed to providing customers with the most valuable Static Pressure Automatic Moulding Line, to ensure the moulding line work effectively and reliably by high performance of configuration.

–The mechanical parts of main and auxiliary equipments machining by CNC machine, the necessary heat treatment to guarantee precision and service life.

–PLC from SimensS7, with touch screen and network Ethernet etc.

–Servo system from SEW or Siemens and and Variable-Frequency Drive from Rexroth.

–Hydraulic valve of moulding machine from Rexroth, Hydraulic Cylinder from China famous brand.

–Low-voltage electrical components from Schneide.

–Hydraulic Seals from international brand.

–Bearing from China famous brand (HRB/LYC/ZWZ).

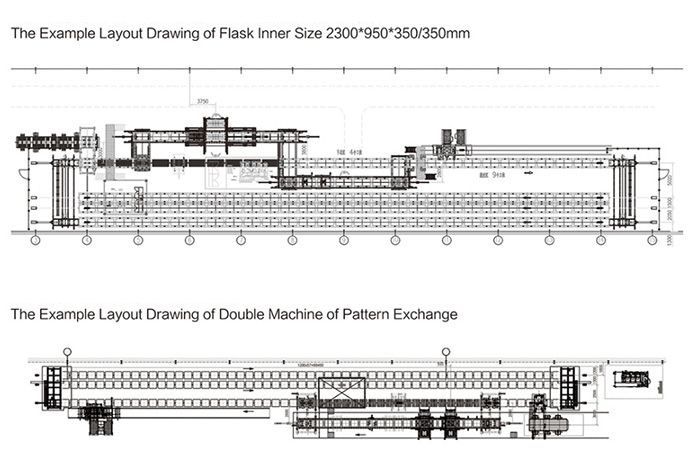

The Example Layout Drawing of Single-Station Machine of Pattern Turnover:

Typical Specification of Single-Station Moulding Line

| Item | Model | |||

| KSP80 | KSP100 | KSP120 | KSP230 | |

| Flask Inner Size(mm) | 800x600x200/200 | 1000x1000x250/250 | 1200x800x350/350 | 2300x950x350/350 |

| Moulding Speed(sec/cycle) | 30 | 30 | 36 | 60 |

| Specific Squeeze Pressure(kgf/cm2) | 8~12 | 8~12 | 8~12 | 8~12 |

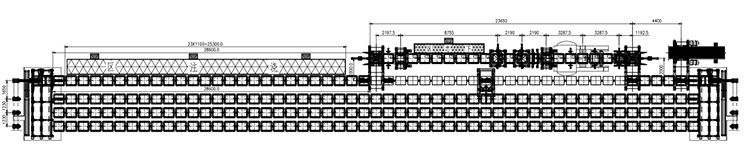

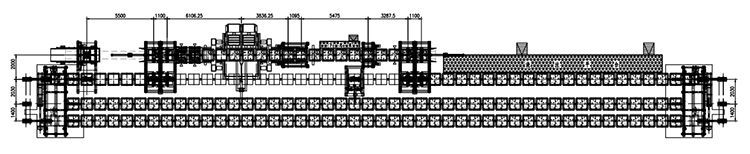

The Example Layout Drawing of Double-Station Machine of Pattern Exchange

Typical Specification of Double-Station Moulding Line

| Item | Model | ||

| SPD80 | SPD100 | SPD120 | |

| Flask Inner Size(mm) | 800x600x200/200 | 1000x1000x250/250 | 1200x800x350/350 |

| Moulding Speed(sec/cycle) | 20 | 20 | 24 |

| Specific Squeeze Pressure(kgf/cm2) | 8~12 | 8~12 | 8~12 |

Product detail pictures:

Related Product Guide:

Injection Moulding Design and Tooling

Modern Era Molding Machines and Industrial Machines

Our goods are commonly recognized and reliable by consumers and may satisfy continually developing economic and social needs for Reasonable price Automatic Barley Fodder Machine - Static Pressure Automatic Moulding Line of Green Sand – Kailong Machinery, The product will supply to all over the world, such as: Austria , Malta , Russia , By integrating manufacturing with foreign trade sectors, we can present total customer solutions by guaranteeing the delivery of right merchandise to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified products and the control of the industry trend as well as our maturity before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

The company keeps to the operation concept scientific management, high quality and efficiency primacy, customer supreme, we have always maintained business cooperation. Work with you,we feel easy!

-

Best-Selling Blowing Moulding Machine - Flask ...

View Detail -

Manufacturing Companies for Carbonated Drink Bo...

View Detail -

Top Quality Macaroni Machine - Moulding box fo...

View Detail -

New Fashion Design for Universal Apron Feeder -...

View Detail -

Wholesale Draft Beer Machine For Sale - Flask ...

View Detail -

Low MOQ for Motor Vibrating Feeder - Semi-Auto...

View Detail