Super Purchasing for Alesage Barycentrique - Continuous Mechanized Moulding Line – Kailong Machinery Detail:

XZ14 Series Joet-Squeeze Moulding Line is the ideal equipment in mass production for foundry factory. Its advantages are less investment, quick returns, reduce labor intensity, raise cast quality, easy operation and maintenance.

The kind of moulding line adopt the joet-squeeze moulding machine, the mould conveyer transfer casting mould go on pouring with cool. The worker carry flask and sand mould through air hang, as well as core filling, match flask, and pouring etc, process adopt semi-automatic operation, the roller machine return flask.

Major equipments compositions are as follows:

◆XZ14 Series Joet-Squeeze Moulding Machine (according to flask size).

◆Mould conveyer.

◆Two way air hang.

◆Poring ring rail, Ladle etc.

◆Fall sand machine.

◆Return flask transport roller machine.

◆Flask (single wall,material:ductile iron).

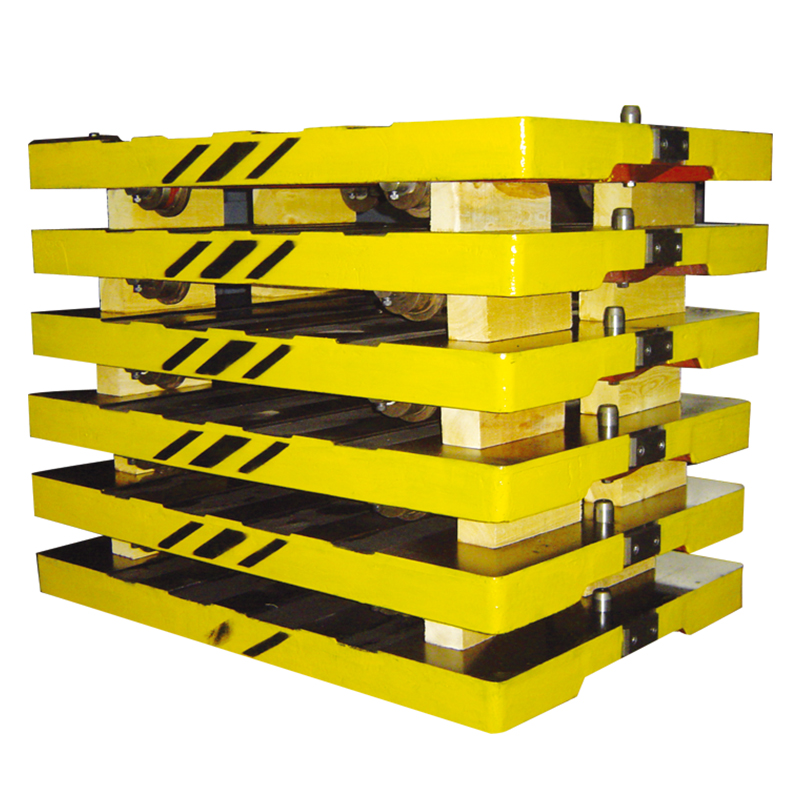

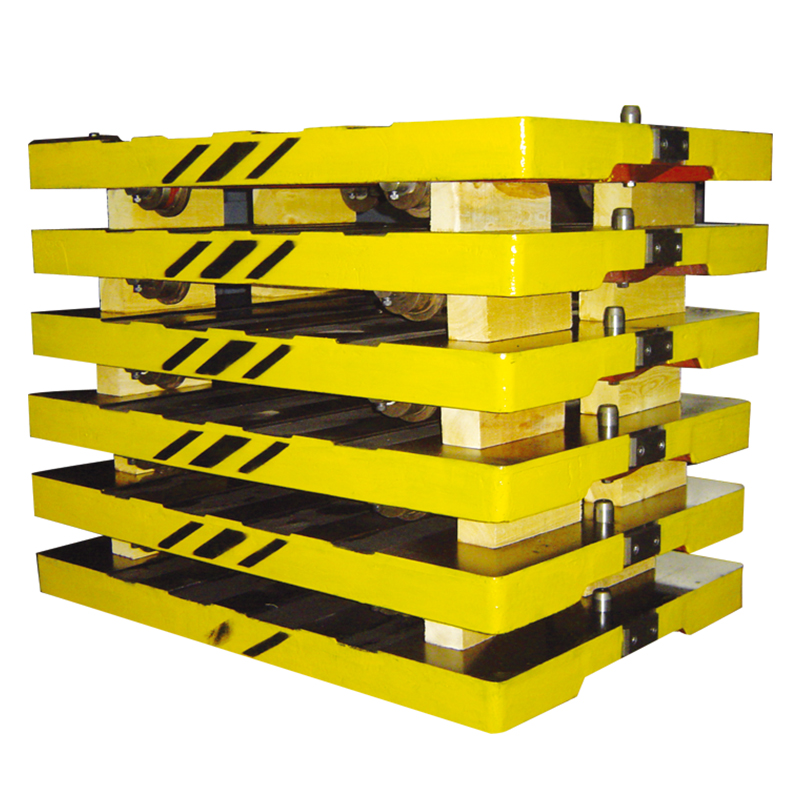

◆ Y21 Series Mould Conveyer

This machine, the equipment collocated for moulding line, makes different process such as moulding, core filling, casting, flask shaking be connected together to form a close moulding line. It is the ideal equipment to realize the moulding mechanization and automation. Generally, it is continuously sperated, but can be beam walking style also as the requirement. The whole length and layout depends on the moulding specifications and the conditions of the workshop.

The Specification Of Continuous Mechanized Moulding Line

| Model | Size Of Pallet Car |

Pitch Of Pallet Car |

Hight Of Pallet Car |

Min Radius Of Turn |

Number Of Rollers |

Motion Speed |

| Y2108 | 800*500 | 1000 | 500 | 1500 | 2 |

1.7-5.8m/min

Adjustable Speed

|

| Y2108A | 4 | |||||

| Y2110 | 1000*650 | 1334 | 500 | 2000 | 4 | |

| Y2110A | ||||||

| Y2112 | 1280*680 | 1668 | 600 | 2500 | 4 | |

| Y2114 | 1400*900 | 1668 | 600 | |||

| Y2116 | 1600*1000 | 2000 | 600 |

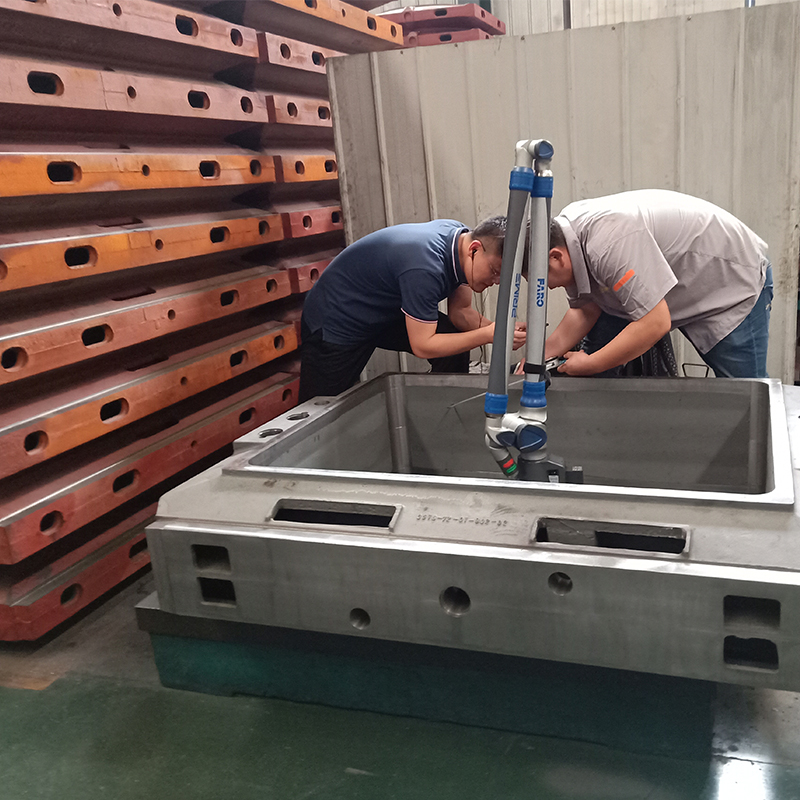

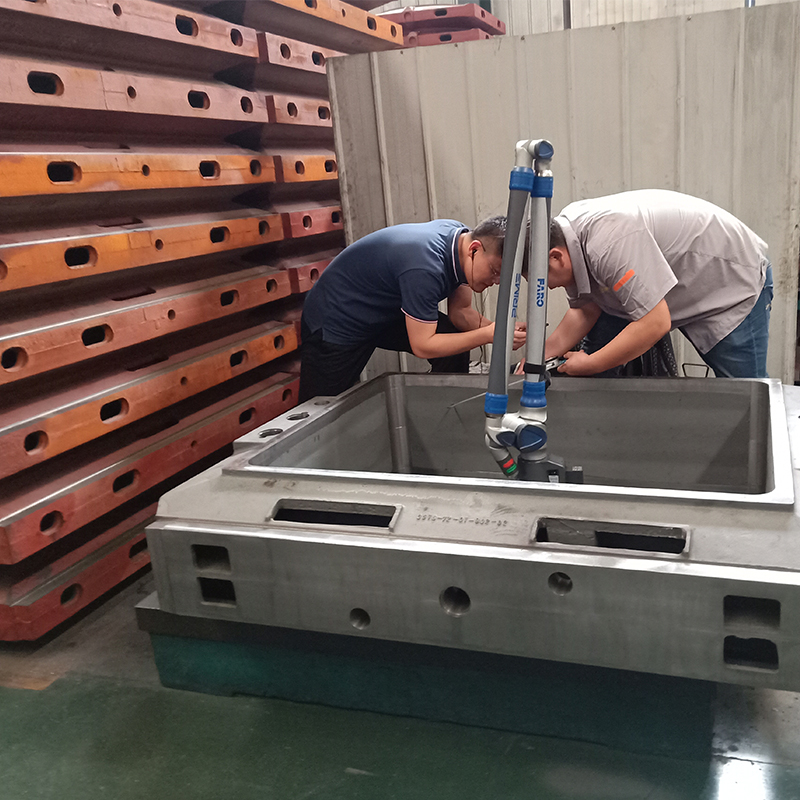

Product detail pictures:

Related Product Guide:

Injection Moulding Design and Tooling

What is Injection Moulding?

With a complete scientific quality management system, good quality and good faith, we win good reputation and occupied this field for Super Purchasing for Alesage Barycentrique - Continuous Mechanized Moulding Line – Kailong Machinery, The product will supply to all over the world, such as: Riyadh , Chile , Jamaica , Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. We've got tightened inspection for quality of product.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!

-

Manufacturer For Relief Valve Hydraulic System ...

View Detail -

Reliable Supplier Paver Automatic Moulding Line...

View Detail -

OEM/ODM Supplier Machine 4060/100w/small/glass ...

View Detail -

Professional Design Pouring Chocolate Molding -...

View Detail -

Super Purchasing for Wbqheavy Duty Apron Chain ...

View Detail -

High reputation China Brick Making Machine - A...

View Detail