Well-designed Oil Pour Machine - Continuous Mechanized Moulding Line – Kailong Machinery Detail:

XZ14 Series Joet-Squeeze Moulding Line is the ideal equipment in mass production for foundry factory. Its advantages are less investment, quick returns, reduce labor intensity, raise cast quality, easy operation and maintenance.

The kind of moulding line adopt the joet-squeeze moulding machine, the mould conveyer transfer casting mould go on pouring with cool. The worker carry flask and sand mould through air hang, as well as core filling, match flask, and pouring etc, process adopt semi-automatic operation, the roller machine return flask.

Major equipments compositions are as follows:

◆XZ14 Series Joet-Squeeze Moulding Machine (according to flask size).

◆Mould conveyer.

◆Two way air hang.

◆Poring ring rail, Ladle etc.

◆Fall sand machine.

◆Return flask transport roller machine.

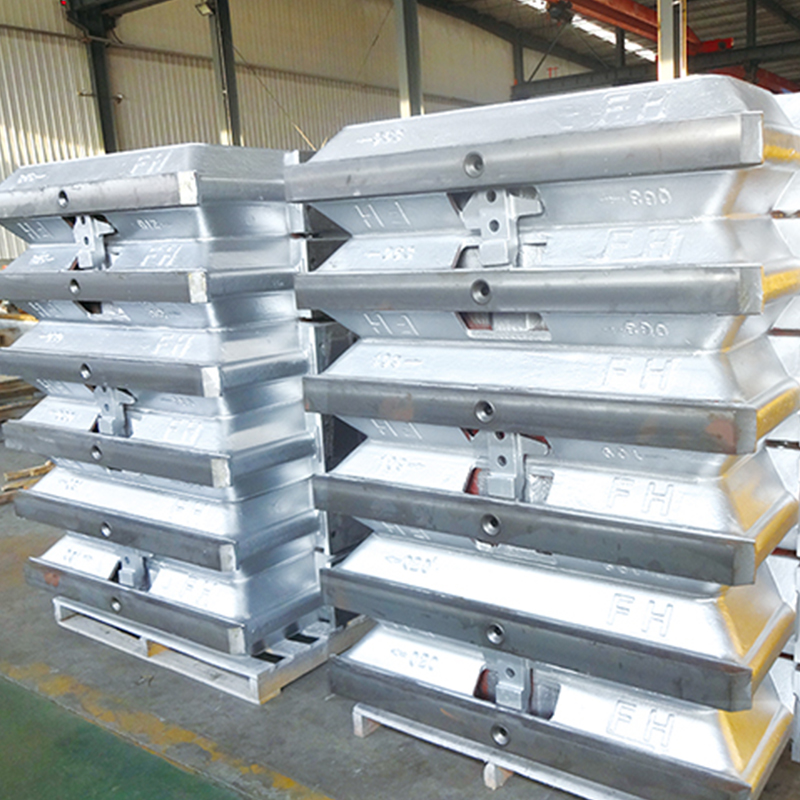

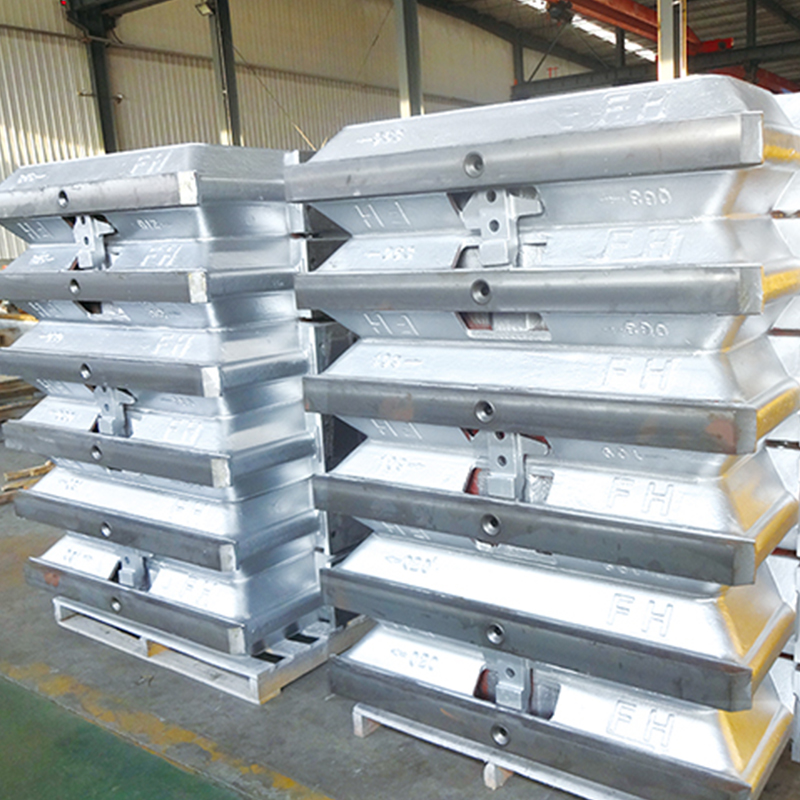

◆Flask (single wall,material:ductile iron).

◆ Y21 Series Mould Conveyer

This machine, the equipment collocated for moulding line, makes different process such as moulding, core filling, casting, flask shaking be connected together to form a close moulding line. It is the ideal equipment to realize the moulding mechanization and automation. Generally, it is continuously sperated, but can be beam walking style also as the requirement. The whole length and layout depends on the moulding specifications and the conditions of the workshop.

The Specification Of Continuous Mechanized Moulding Line

| Model | Size Of Pallet Car |

Pitch Of Pallet Car |

Hight Of Pallet Car |

Min Radius Of Turn |

Number Of Rollers |

Motion Speed |

| Y2108 | 800*500 | 1000 | 500 | 1500 | 2 |

1.7-5.8m/min

Adjustable Speed

|

| Y2108A | 4 | |||||

| Y2110 | 1000*650 | 1334 | 500 | 2000 | 4 | |

| Y2110A | ||||||

| Y2112 | 1280*680 | 1668 | 600 | 2500 | 4 | |

| Y2114 | 1400*900 | 1668 | 600 | |||

| Y2116 | 1600*1000 | 2000 | 600 |

Product detail pictures:

Related Product Guide:

What is Injection Moulding?

What Do You Need To Know About Your Injection Moulding Machine?

We are ready to share our knowledge of marketing worldwide and recommend you suitable products at most aggressive costs. So Profi Tools offer you finest benefit of money and we are ready to produce alongside one another with Well-designed Oil Pour Machine - Continuous Mechanized Moulding Line – Kailong Machinery, The product will supply to all over the world, such as: Eindhoven , Plymouth , Hungary , Our company's main items are widely used all over the world; 80% of our products and solutions exported to the United States, Japan, Europe and other markets. All stuff sincerely welcome guests come to visit our factory.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!

-

Factory Price Automatic Molding Line - Automat...

View Detail -

OEM Customized Pvc Baseboard Moulding - High Q...

View Detail -

Factory Price Rotary Automatic Pu Molding Machi...

View Detail -

18 Years Factory Injection Blow Moulding Machin...

View Detail -

Super Purchasing for Smc Products Production Li...

View Detail -

PriceList for Manual Candle Machine - Semi-Aut...

View Detail