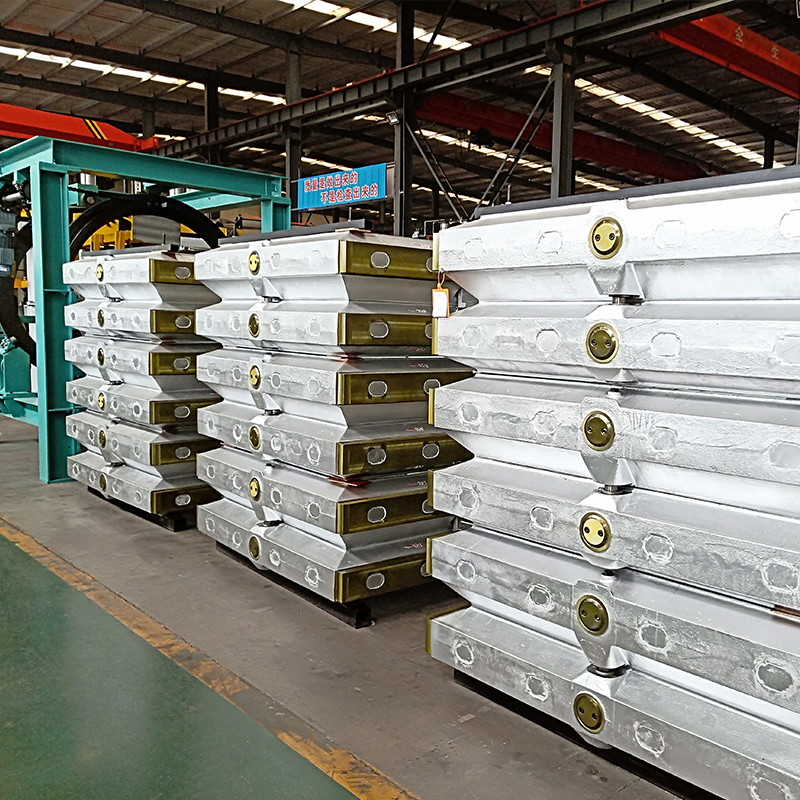

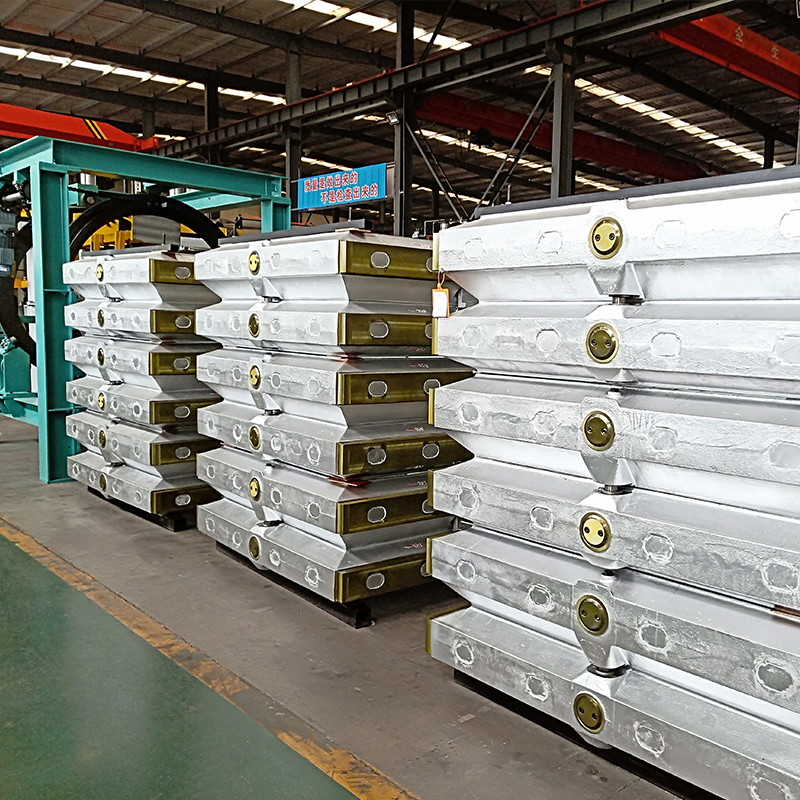

Well-designed Rail Track - Automatic Horizontal Flaskless Moulding Machine – Kailong Machinery Detail:

Typical Specification of Moulding Machine

| Item | Model | ||

| KSF50 | KSF60 | KSF70 | |

| Flask Inner Size(mm) | 500x400x150/150 | 600x500x200/200 | 700x600x250/250 |

| Moulding Speed(Without Core Setting)(sec/cycle) | 30 | 30 | 36 |

| Squeeze Surface Pressure(kgf/cm2) | 8~12 | 8~12 | 8~12 |

| Hardness of Horizontal Surface & Parting Surface |

80°~92°(GF Hardness Tester) | ||

| Hardness of Mold Side | 85°~90°(GF Hardness Tester) | ||

| Moulding Rate | ≥98% | ||

KSF horizontal parting and flask-striped shooting-squeezing molding line adopt the sand shooting, with horizontal parting, slip flask and weight. Easy core setting, easy operation, high automation, the molding lines are widely used in mass-production for small-sized castings. The whole line consist of molding machine, sand conveyor line, slip flask and weight taking and droping device, indexing transport and cushioning device, synchronous cooling belt, pouring machine, etc.

Product detail pictures:

Related Product Guide:

Injection Moulding Design and Tooling

What is Injection Moulding?

Dependable good quality and very good credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of quality initial, shopper supreme for Well-designed Rail Track - Automatic Horizontal Flaskless Moulding Machine – Kailong Machinery, The product will supply to all over the world, such as: Moscow , Porto , Kenya , Products have been exported to Asia, Mid-east,European and Germany market. Our company has constantly been able to update the products performance and safety to meet the markets and strive to be top A on stable quality and sincere service. If you have the honor to do business with our company. we will definitely do our very best to support your business in China.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.

-

Original Factory Electric Coconut Grating Machi...

View Detail -

Wholesale Dealers of 20l Pet Blow Moulding Mach...

View Detail -

Renewable Design for Eva Shoe Soles Making Mach...

View Detail -

Massive Selection for Hdpe Pipe Machine - Flas...

View Detail -

New Fashion Design for Plastic Roof Tile Machin...

View Detail -

Manufacturing Companies for Meat Roll Moulding ...

View Detail