Wholesale Price Pouring Copper Coating Machine - Static Pressure Automatic Moulding Line of Green Sand – Kailong Machinery Detail:

Static pressure moulding technical refers to airflow with hydraulic multi-piston squeeze compaction technology, according to the difficulty of compaction, can choose only hydraulic multi-piston squeeze compaction or airflow and hydraulic multi-piston squeeze compaction.

Static Pressure has following advantages.

◆High ability for compaction sand, rigid and dense mould, suitable to manufacture of complex castings.

◆Dimensional stability and better surface roughness.

◆High efficiency of moulding.

◆Mould plate with high rate of utilization.

◆Good working condition and labour saving.

Kailong Machinery is committed to providing customers with the most valuable Static Pressure Automatic Moulding Line, to ensure the moulding line work effectively and reliably by high performance of configuration.

–The mechanical parts of main and auxiliary equipments machining by CNC machine, the necessary heat treatment to guarantee precision and service life.

–PLC from SimensS7, with touch screen and network Ethernet etc.

–Servo system from SEW or Siemens and and Variable-Frequency Drive from Rexroth.

–Hydraulic valve of moulding machine from Rexroth, Hydraulic Cylinder from China famous brand.

–Low-voltage electrical components from Schneide.

–Hydraulic Seals from international brand.

–Bearing from China famous brand (HRB/LYC/ZWZ).

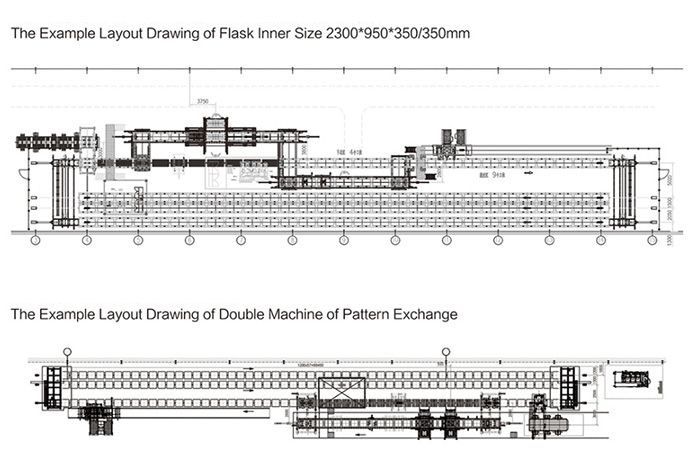

The Example Layout Drawing of Single-Station Machine of Pattern Turnover:

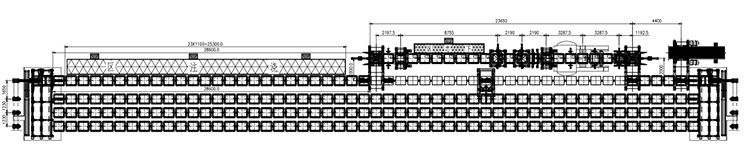

Typical Specification of Single-Station Moulding Line

| Item | Model | |||

| KSP80 | KSP100 | KSP120 | KSP230 | |

| Flask Inner Size(mm) | 800x600x200/200 | 1000x1000x250/250 | 1200x800x350/350 | 2300x950x350/350 |

| Moulding Speed(sec/cycle) | 30 | 30 | 36 | 60 |

| Specific Squeeze Pressure(kgf/cm2) | 8~12 | 8~12 | 8~12 | 8~12 |

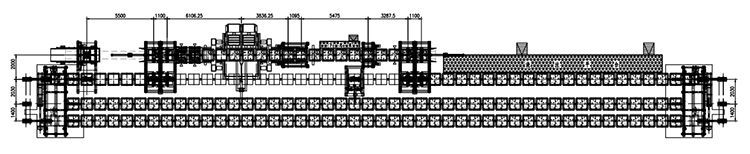

The Example Layout Drawing of Double-Station Machine of Pattern Exchange

Typical Specification of Double-Station Moulding Line

| Item | Model | ||

| SPD80 | SPD100 | SPD120 | |

| Flask Inner Size(mm) | 800x600x200/200 | 1000x1000x250/250 | 1200x800x350/350 |

| Moulding Speed(sec/cycle) | 20 | 20 | 24 |

| Specific Squeeze Pressure(kgf/cm2) | 8~12 | 8~12 | 8~12 |

Product detail pictures:

Related Product Guide:

What Do You Need To Know About Your Injection Moulding Machine?

What is Injection Moulding?

We constantly believe that one's character decides products' high quality, the details decides products' high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for Wholesale Price Pouring Copper Coating Machine - Static Pressure Automatic Moulding Line of Green Sand – Kailong Machinery, The product will supply to all over the world, such as: Zurich , Barbados , Bolivia , We have the best products and professional sales and technical team.With the development of our company, we are able to provide customers best products, good technical support, perfect after-sales service.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.

-

OEM manufacturer Energy Saving Blow Moulding Ma...

View Detail -

OEM Customized Automatic Pu Shoe Injection Mach...

View Detail -

100% Original Factory Injection Moulding Pu Mac...

View Detail -

Special Price for Blower For Led Lamp Cover - ...

View Detail -

China Gold Supplier for Eps Decorative Line Mou...

View Detail -

Leading Manufacturer for Banana Type Machine - ...

View Detail