Manufacturing Companies For Flask Separating Device - Continuous Mechanized Moulding Line – Kailong Detail:

XZ14 Series Joet-Squeeze Moulding Line is the ideal equipment in mass production for foundry factory. Its advantages are less investment, quick returns, reduce labor intensity, raise cast quality, easy operation and maintenance.

The kind of moulding line adopt the joet-squeeze moulding machine, the mould conveyer transfer casting mould go on pouring with cool. The worker carry flask and sand mould through air hang, as well as core filling, match flask, and pouring etc, process adopt semi-automatic operation, the roller machine return flask.

Major equipments compositions are as follows:

◆XZ14 Series Joet-Squeeze Moulding Machine (according to flask size).

◆Mould conveyer.

◆Two way air hang.

◆Poring ring rail, Ladle etc.

◆Fall sand machine.

◆Return flask transport roller machine.

◆Flask (single wall,material:ductile iron).

◆ Y21 Series Mould Conveyer

This machine, the equipment collocated for moulding line, makes different process such as moulding, core filling, casting, flask shaking be connected together to form a close moulding line. It is the ideal equipment to realize the moulding mechanization and automation. Generally, it is continuously sperated, but can be beam walking style also as the requirement. The whole length and layout depends on the moulding specifications and the conditions of the workshop.

The Specification Of Continuous Mechanized Moulding Line

| Model | Size Of Pallet Car |

Pitch Of Pallet Car |

Hight Of Pallet Car |

Min Radius Of Turn |

Number Of Rollers |

Motion Speed |

| Y2108 | 800*500 | 1000 | 500 | 1500 | 2 |

1.7-5.8m/min

Adjustable Speed

|

| Y2108A | 4 | |||||

| Y2110 | 1000*650 | 1334 | 500 | 2000 | 4 | |

| Y2110A | ||||||

| Y2112 | 1280*680 | 1668 | 600 | 2500 | 4 | |

| Y2114 | 1400*900 | 1668 | 600 | |||

| Y2116 | 1600*1000 | 2000 | 600 |

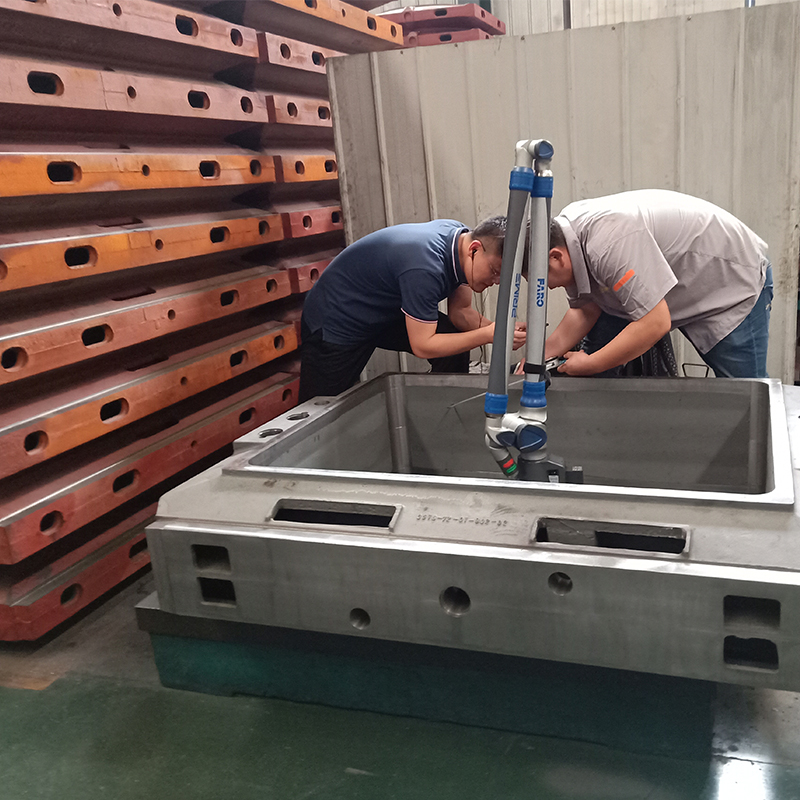

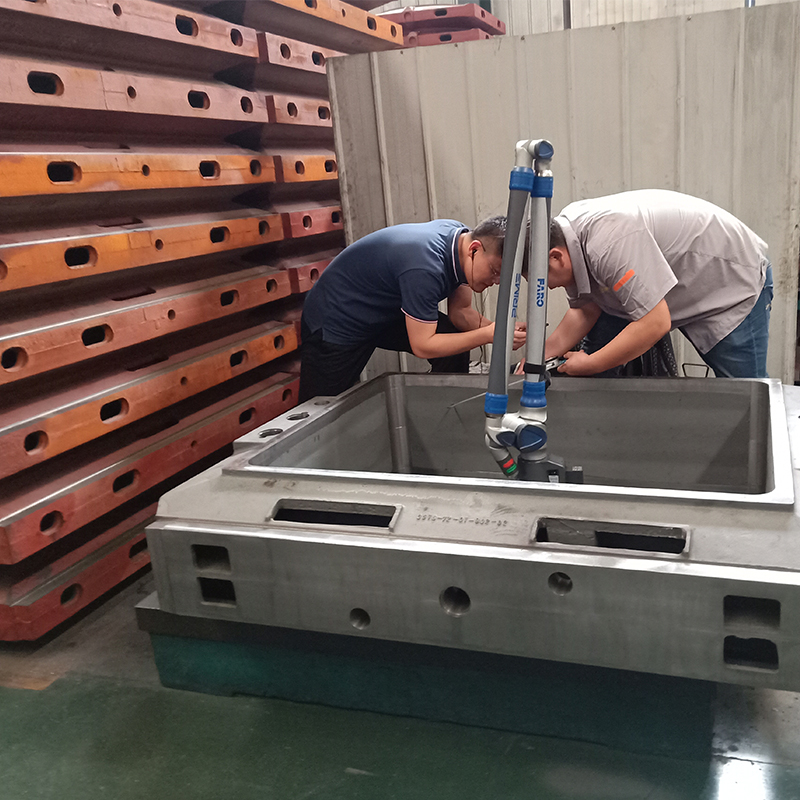

Product detail pictures:

Related Product Guide:

Modern Era Molding Machines and Industrial Machines

Injection Moulding Design and Tooling

With our excellent management, strong technical capability and strict quality control system, we continue to provide our clients with reliable quality, reasonable prices and excellent services. We aim at becoming one of your most reliable partners and earning your satisfaction for Manufacturing Companies For Flask Separating Device - Continuous Mechanized Moulding Line – Kailong, The product will supply to all over the world, such as: United Arab Emirates , Costa rica , Dubai , Our company abides by the management idea of keep innovation, pursue excellence. On the basis of assuring the advantages of existing merchandise, we continuously strengthen and extend product development. Our company insists on innovation to promote the sustainable development of enterprise, and make us become the domestic high-quality suppliers.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.

-

Chinese wholesale Filling Dispensing Machines -...

View Detail -

Reliable Supplier Apron Conveyor For Big Bulk M...

View Detail -

Ordinary Discount China Belt Scale Controller -...

View Detail -

Factory Promotional Pvc Edge Banding Extrusion ...

View Detail -

High reputation High Quality Sand Production Li...

View Detail -

Super Purchasing for Alesage Barycentrique - F...

View Detail