Rapid Delivery for Best Polished Pouring Machine - Automatic Horizontal Flaskless Moulding Machine – Kailong Machinery Detail:

Typical Specification of Moulding Machine

| Item | Model | ||

| KSF50 | KSF60 | KSF70 | |

| Flask Inner Size(mm) | 500x400x150/150 | 600x500x200/200 | 700x600x250/250 |

| Moulding Speed(Without Core Setting)(sec/cycle) | 30 | 30 | 36 |

| Squeeze Surface Pressure(kgf/cm2) | 8~12 | 8~12 | 8~12 |

| Hardness of Horizontal Surface & Parting Surface |

80°~92°(GF Hardness Tester) | ||

| Hardness of Mold Side | 85°~90°(GF Hardness Tester) | ||

| Moulding Rate | ≥98% | ||

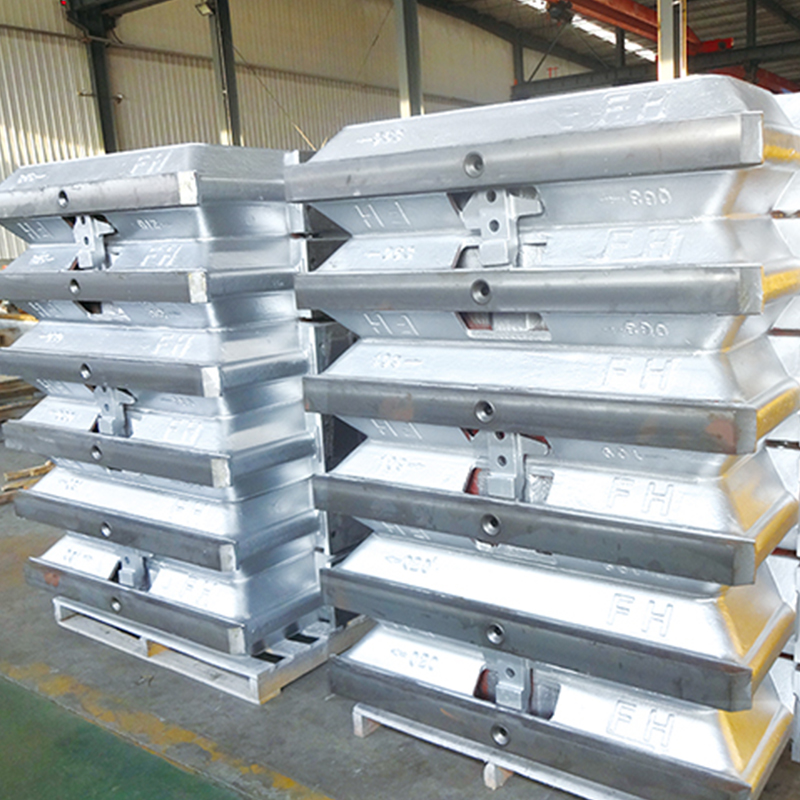

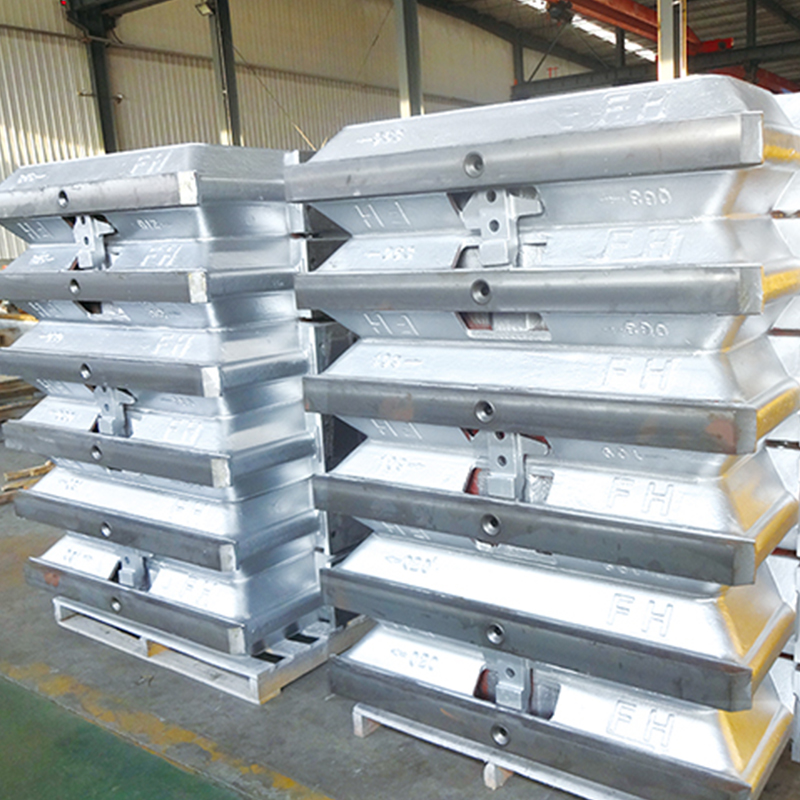

KSF horizontal parting and flask-striped shooting-squeezing molding line adopt the sand shooting, with horizontal parting, slip flask and weight. Easy core setting, easy operation, high automation, the molding lines are widely used in mass-production for small-sized castings. The whole line consist of molding machine, sand conveyor line, slip flask and weight taking and droping device, indexing transport and cushioning device, synchronous cooling belt, pouring machine, etc.

Product detail pictures:

Related Product Guide:

What Do You Need To Know About Your Injection Moulding Machine?

How Does an Injection Moulding Machine Work?

To be able to give you benefit and enlarge our business, we also have inspectors in QC Team and assure you our greatest service and products for Rapid Delivery for Best Polished Pouring Machine - Automatic Horizontal Flaskless Moulding Machine – Kailong Machinery, The product will supply to all over the world, such as: Brunei , Brazil , Melbourne , Besides strong technical strength, we also introduce advanced equipment for inspection and conduct strict management. All the staff of our company welcome friends both at home and abroad to come for visits and business on the basis of equality and mutual benefit. If you are interested in any of our items, please feel free to contact us for quotation and product details.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!

-

Factory directly Foundry Moulding Machine - Fl...

View Detail -

High definition Small Plastic Products Making M...

View Detail -

Newly Arrival Polycarbonate Moulding Machine - ...

View Detail -

8 Year Exporter Pvc Ceiling Making Machines - ...

View Detail -

OEM/ODM China Metal Filling Unit - Flask for M...

View Detail -

Hot Selling for Cnc Machine Belt Chip Conveyor ...

View Detail